UMA / 產品介紹 / 影像模組測試

IM-1000CX

1

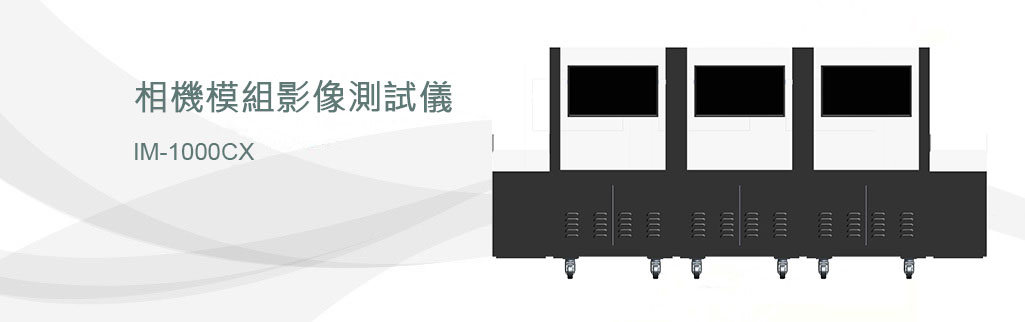

IM-1000CX

Full Functions Camera Module Image Quality Tester

Description

IM-1000CX Image Quality Tester provides high precision multiple test items of image quality for camera module inspection. This system consists of several test stations that can be flexibly replaced based on different test requirements, such as intrinsic, MTF, and distortion test. The maximum Field of View can up to 180 degrees, which is suitable for a variety of image module in different application fields, including surveillance, sport, and automotive, etc.

• The digitalized quality full inspection for various kind of camera module can be achieved via multiple stations test, intrinsic calibration, Resolution, and distortion, with multiple test items of each station.

• The maximum FOV(Field of View)is up to 180 degrees , which can fulfill the test requirements of different kinds of camera modules, such as surveillance, sport and automotive, etc

• Dual-Line with Multi-Station transportation system design allows operating subjects load/unload while testing for reducing the total cycle time.

• Fast Jig switch design can meet small-volume and variety of models production requirements. This system also can be customized by following the client’s production plan.

• LEGO type test station design provides high flexibility for different test item combination needs.

Full Functions Camera Module Image Quality Tester

Description

IM-1000CX Image Quality Tester provides high precision multiple test items of image quality for camera module inspection. This system consists of several test stations that can be flexibly replaced based on different test requirements, such as intrinsic, MTF, and distortion test. The maximum Field of View can up to 180 degrees, which is suitable for a variety of image module in different application fields, including surveillance, sport, and automotive, etc.

• The digitalized quality full inspection for various kind of camera module can be achieved via multiple stations test, intrinsic calibration, Resolution, and distortion, with multiple test items of each station.

• The maximum FOV(Field of View)is up to 180 degrees , which can fulfill the test requirements of different kinds of camera modules, such as surveillance, sport and automotive, etc

• Dual-Line with Multi-Station transportation system design allows operating subjects load/unload while testing for reducing the total cycle time.

• Fast Jig switch design can meet small-volume and variety of models production requirements. This system also can be customized by following the client’s production plan.

• LEGO type test station design provides high flexibility for different test item combination needs.

2

| First Test Station | Inspection Items | Unit |

| Intrinsic Calibration |

Luminance Uniformity(The brightness ratio between center and comer) | % |

| Vignetting (Brightness core or brightness counter line) |

||

| Bad Pixel | Bad Pixel (Full White at center area) | pixels |

| Bad Pixel (Full Dark) | pixels | |

| Blemish | Particles on image | Ratio, pixels, numbers. |

|

Second Test Station |

|

|

|

Resolution (ISO 12233) |

MTF(Modulation Transfer Function) |

lp/mm |

|

SFR (Spatial Frequency Response) |

lp/mm |

|

|

Alignment |

Decenter (ocx, ocy) |

pixel |

|

Rotation |

Amount of positive clocking or anti-clocking |

degree |

|

Third Test Station |

|

|

|

Distortion (ISO 17850) |

Optical distortion |

% |